In the last update it was reported that work had progressed on the design and delivery of the parts to create the build fixture required to begin the process of re-assembling the fuselage. Although there was a holding fixture for the fuselage, Airframe Assemblies (AA) identified that a specific build fixture was required, an unexpected expenditure but one that the rebuild could not do without.

Work was slow during January 2020, at least as far as visible progress was concerned, as AA placed the orders for the final pieces of the fixture and were waiting on the contractors for delivery. To ensure that work was able to progress uninterrupted a monthly ‘spend-limit’ had to be set which meant that AA could not carry out any additional work throughout most of January.

During the last week of January and February initial work on the new fixture commenced. For the guys working in the industry this stage is something they have seen many times on vintage aircraft and they often see this as:

“about as interesting as watching paint dry, not at all photogenic”

However, for the HTPG team and everyone following the project this is an exciting time. With receipt of all the main parts AA have begun to cut various pieces of aluminium angle and then accurately drill fixing holes. On completion of this stage they can then begin the process of assembling the many pieces.

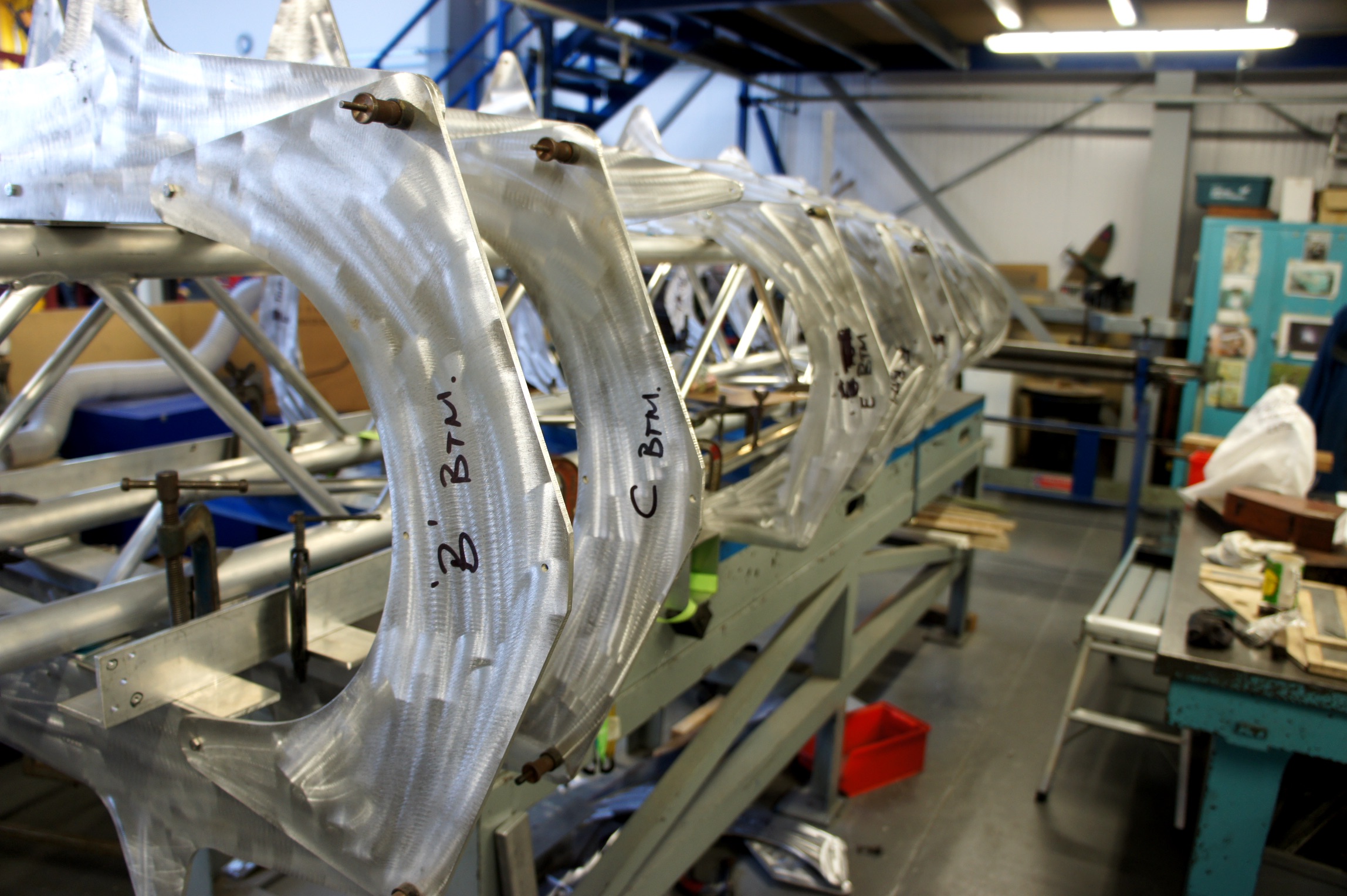

Now at last it begins to look like something usable. The first stage has been to set up the central ‘gantry beam’ on the surface table to make sure all is perfectly level. The first of the frame points was positioned, drilled and bolted in place. This is a critical step as it gives a datum to start from, so that the next one can be positioned in the correct relationship to the first. If the first frame is not correctly positioned, then all of the remaining frames will be out of position.

This entire process is then repeated for each of the ten separate frame stations. All of this is done old-school style, dimensional checks using a stick-micrometer, Vernier height gauge, optical transit scope etc. This process highlights the skills that the experts in this field maintain, physically setting up fixtures such as this is a slow and tedious, but highly skilled business.

Once all the frame points have been positioned correctly the central beam will then be mounted on steel end frames, to form a ‘roll over type jig’, which will enable 360o rotation and complete access during reassembly.

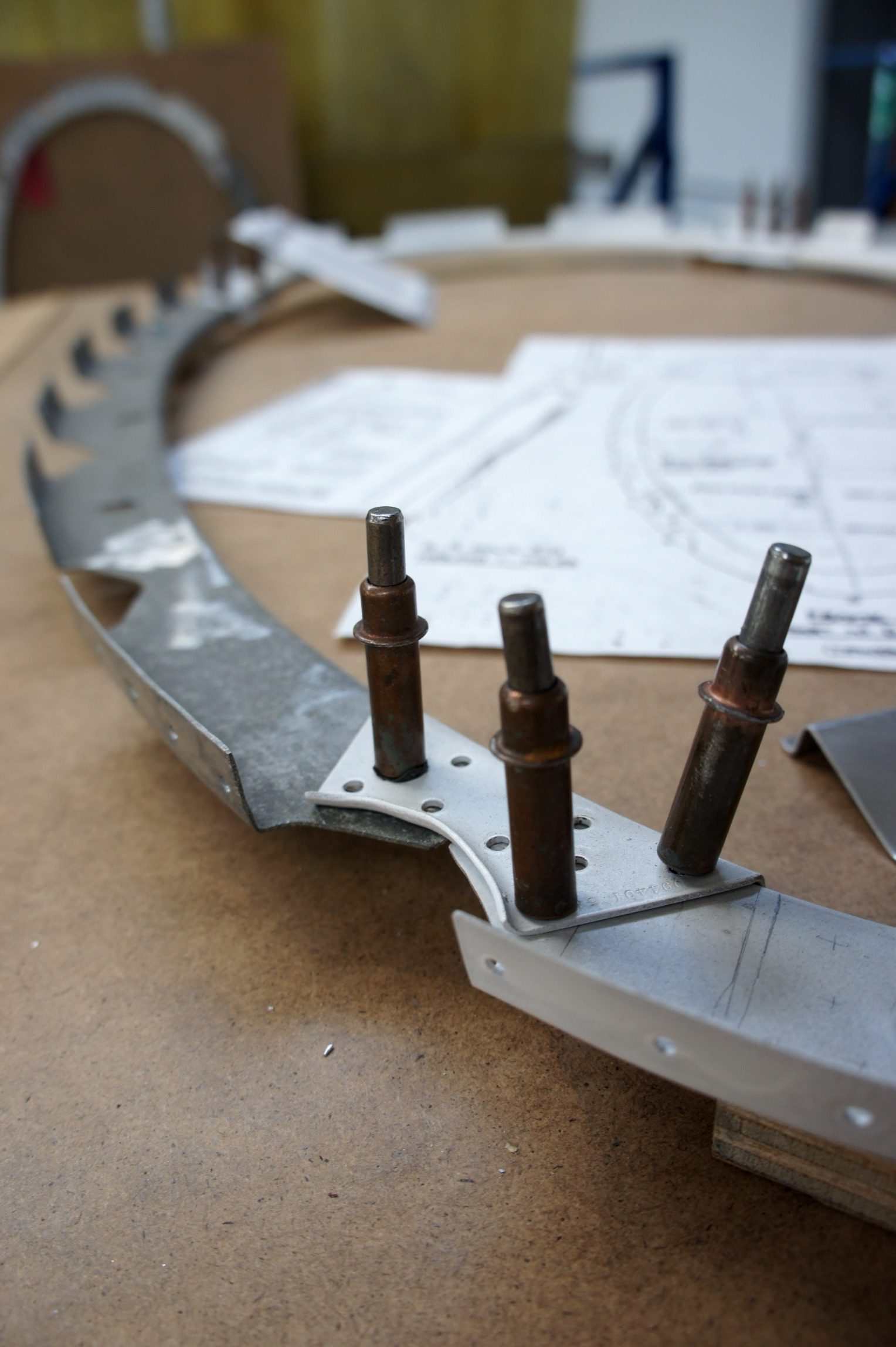

Although the build fixture had taken up most of the ‘spend-limit’ there have been opportunities for AA to continue a small amount of work on frame repairs. As each frame was removed from the fuselage it was mounted on a board, allowing for safe storage and making it easier to work on. As seen on a recent members’ visit to AA various sections of damaged or corroded frame have been addressed and primed, in most instances the original sections have been repaired but there have been a very small number that have had to be remade.

Up to the date of this update £71,000 has been spent on the significant work to date. Despite the best efforts of the fundraising team, with the world reeling from the COVID-19 pandemic, the difficult decision has had to be taken to halt the spending on the rebuild of RB396’s rear fuselage. This is just a pause, not a complete stoppage, although until the pandemic begins to slow, and the UK Government restrictions are relaxed or removed, it is expected that there will be a cash flow shortage. This is already being felt within the charity, with shop sales and donations falling dramatically in April, despite the 1st April anniversary events, for the 75th anniversary of RB396’s final flight. Temporarily pausing the rebuild spending will allow the project to keep a reserve in order to cover the charity running costs, any pre-season costs (any airshows/events and stock) and a portion of the funds we need to raise to secure the cache of parts including the rear frame. Essentially it will allow the charity to stay afloat during these difficult times. We have approximately £130,000 – £170,000 left to raise for the rear fuselage to be complete. In the event that large sums of money can be raised, and AA are deemed safe to work, then the rebuild can continue and even accelerate. It all comes down to funds.

The launching of the new Platinum Club, for those in a position to make higher contributions towards the project’s work, has been the saviour of the project since its launch on the 1st April. Without the funds raised and pledged by those signing up to the scheme, the landscape for the remainder of this year for the project would look very different. If you would like to know more and join those already helping the project to keep afloat, please see the “Get Involved” page of this website.

It is worth noting, as has been mentioned in previous updates, that re-using sections of the rear fuselage is often significantly more expensive than re-making them from new. This is being done for authenticity, and as much as 80% of the rear fuselage is being re-used in this fashion, giving RB396 the historical credence she deserves. Even in these difficult times, this is not something that will be compromised.

There has been a lot of hard work by our dedicated volunteer team and their dedication has been rewarded with continued progress. Our fundraising efforts will never stop, and that is the team is all working so hard on.

We are the fundraisers, not the engineers, enabling and facilitating the rebuild of this forgotten legend. A huge thank you must go to all our supporters and contributors for helping us to get to this significant stage of the project.