Since our six month progress update the rebuild at Airframe Assemblies has been continuing. We are really pleased to be able to bring you some more detail of that work, highlighting what the hard working and dedicated team of volunteers, raising the funds required for the rebuild, has been able to achieve.

Since our six month progress update the rebuild at Airframe Assemblies has been continuing. We are really pleased to be able to bring you some more detail of that work, highlighting what the hard working and dedicated team of volunteers, raising the funds required for the rebuild, has been able to achieve.

The stringers are rolled ‘top hat’ section (Hawker A.std 1067) made from 22 swg light alloy, which are then attached to the skin panels by 1/8” countersunk rivets which all had to be painstakingly removed by hand (over 5000 in total).

With this complete the messy and onerous task of paint stripping was next. Since the last update this has now all been completed and underneath the many layers of paint the stringers were in very good condition.

Each stringer section is then clipped back in position onto its respective skin panel, to allow safe storage and to ensure they are not mixed in the process.

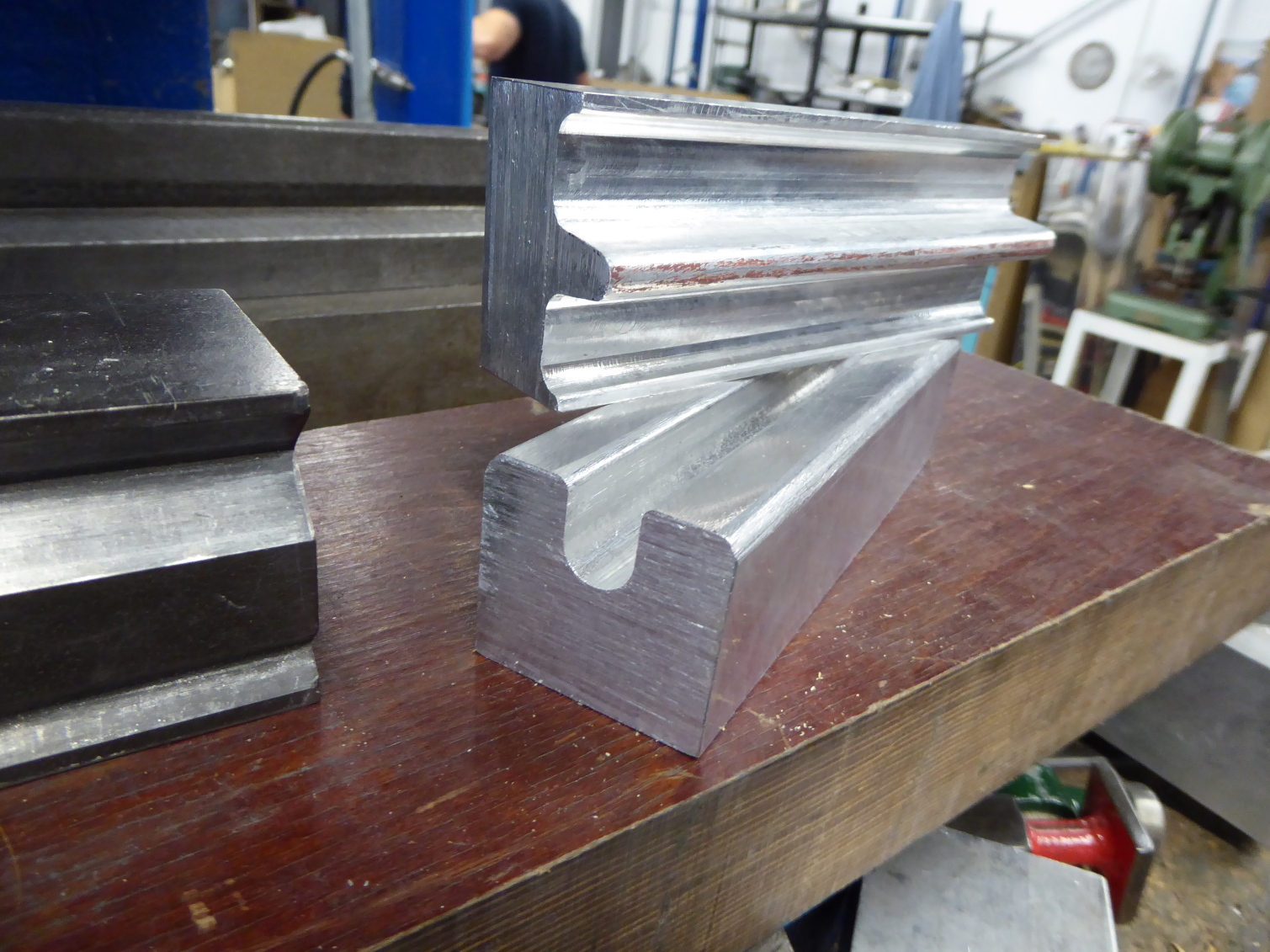

Each of the stringers has an individual assessment completed to determine which can be saved, those that need minor repair and those that may need more extensive repairs in line with the official repair manual. There are numerous dents and edge ripples in places that require straightening and to avoid the need to hand bash each defect Airframe Assemblies have made a special press tool. This accurately matches the stringer profile and gently presses out the dents, with a little help from a small fly-press. Work has also continued on frame ‘A’ along with the first stage of the mounting plates for the build fixture, more to come of this in later updates…

Each of the stringers has an individual assessment completed to determine which can be saved, those that need minor repair and those that may need more extensive repairs in line with the official repair manual. There are numerous dents and edge ripples in places that require straightening and to avoid the need to hand bash each defect Airframe Assemblies have made a special press tool. This accurately matches the stringer profile and gently presses out the dents, with a little help from a small fly-press. Work has also continued on frame ‘A’ along with the first stage of the mounting plates for the build fixture, more to come of this in later updates…

This update highlights where the costs are accrued in the rebuild of a unique aircraft, we need the support of everyone to get RB396 back where she belongs. Just £2 (the average price of a half a pint in your local) from each of our followers on Social Media would see the rebuild of the rear fuselage completed, please do help and visit the donation page or our webshop. Thank you to all those who have contributed to the project so far.

To visit the Donation page click here: Donate

To visit out shop please click here: Shop

Visit our gallery for more updates…

https://hawkertyphoon.com/gallery/airframe-assemblies-progress-jul-sept-2019