After a lot of hard work by the trustees and dedicated volunteers, May 2019 saw Airframe Assemblies (AA) contracted to rebuild RB396’s rear fuselage. The results of the preliminary inspection carried out by AA were very positive and they indicated that as much as 60% of the original internal structure would be suitable for rebuild rather than replacement, their remit to use as much of RB396’s structure as safely possible.

After a lot of hard work by the trustees and dedicated volunteers, May 2019 saw Airframe Assemblies (AA) contracted to rebuild RB396’s rear fuselage. The results of the preliminary inspection carried out by AA were very positive and they indicated that as much as 60% of the original internal structure would be suitable for rebuild rather than replacement, their remit to use as much of RB396’s structure as safely possible.

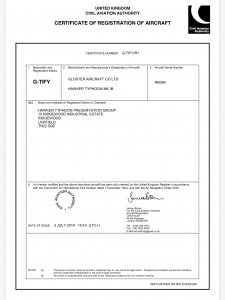

At this stage RB396 was not registered with the CAA which caused a little delay, AA were not able to begin work in earnest until this happened. They were able to remove the first skin to carry out the assessment without impacting the CAA’s requirements and so for the first time since the Typhoon was withdrawn from service work to airworthy status had begun.

With the paperwork and registration of G-TIFY complete, real work could begin which has seen a number of steps completed:

With the paperwork and registration of G-TIFY complete, real work could begin which has seen a number of steps completed:

- Fuselage completely stripped to its component parts

- Frame J assessed, cleaned, undercoated and signed off

- Frame A (the largest and heaviest) stripped and assessed

- Stringers de-riveted from the skins, approx. 200 rivets per stringer, 26 stringers taking 2 minutes per rivet

- Paperwork for each part has been started

- Tooling designed for the top hat section repairs

- Tooling designed and work started on a jig for the rear fuselage, the fixture we have will be utilised for storage once the fuselage is complete

- Repair process (AP Repair Manual) assessed and approved for the sections of rib and stringers that will need replacing.

The biggest challenge for any restoration is corrosion. Each aircraft was designed and built to fulfil a role with no expectation that they would be flying over 70 years later, protection against corrosion was not a priority. We are very fortunate in that there is minimal corrosion in RB396 however, there is a large amount of damage to the structure from the forced landing and the subsequent years on public display.

In just 6 months in residence with AA there has been significant progress. The repair of one of the damaged ribs and the repair processes involved are unique insight into the job at hand, one that requires specialist care. Frame J top segment (Pt No. D94406-21), was found to be badly distorted and required flattening out and various imperfections dressed. First the part has to undergo suitable heat treatment to temporarily soften the material, otherwise there is a grave risk of cracking the item.

In just 6 months in residence with AA there has been significant progress. The repair of one of the damaged ribs and the repair processes involved are unique insight into the job at hand, one that requires specialist care. Frame J top segment (Pt No. D94406-21), was found to be badly distorted and required flattening out and various imperfections dressed. First the part has to undergo suitable heat treatment to temporarily soften the material, otherwise there is a grave risk of cracking the item.

The heat treatment process involves heating the item to 5050C for around 20 minutes, it is then quenched in cold water. This leaves the material ‘workable’ for around 2 hours, after a couple of days it will naturally return to its original hardness/strength. The time and temperature is a critical process carried out in a computer controlled calibrated oven.

With the piece successfully dressed flat, edges are smoothed as the original rather ‘saw tooth’ factory finishing left a lot to be desired, but there was a war on! Next step is a chemical dip and basic clean to kill off any surface corrosion. When complete it is ‘alocromed’, a chemical surface treatment that prevents corrosion and prepares the surface for the initial coat of primer, in this case white as the final internal colour yet to be confirmed.

So that is what it takes to save a piece of history, around a full working day for just this one item.

Now that AA have disassembled and assessed the entire rear fuselage, the initial estimate of 60% re-usable parts, has been revised. We are delighted to now state, that following the inspections of all the sections, it is estimated that approximately 80% of RB396’s rear fuselage can be re-used in the rebuild. This really does increase the historical significance of the rebuild of this genuine WWII combat veteran Hawker Typhoon. It is worth noting that it is not cheaper to re-use many parts, it is in fact more expensive than simply creating new, in most cases. However, our focus has always been on ensuring this potential one of a kind aircraft is rebuilt to the highest, and most authentic standards possible.

Our fundraising does not stop, we still need to raise the funds to complete the fuselage and to next section to be started in the early part of 2020. The amount required to complete the rebuild of this section, following the successful Crowdfunder and monies raised since, stands at around £100,000. Without our supporters we would not have been able to reach this stage but we need continued support as the level of work increases.

Our fundraising does not stop, we still need to raise the funds to complete the fuselage and to next section to be started in the early part of 2020. The amount required to complete the rebuild of this section, following the successful Crowdfunder and monies raised since, stands at around £100,000. Without our supporters we would not have been able to reach this stage but we need continued support as the level of work increases.

To donate towards the rebuild effort, please visit the “donate” section of our website, by clicking here.